enjoy!

Central Iowa Hoist Inspections

Safety, Reliability, and Peace of Mind: Hire Knowledgeable Hoist Inspectors Today!

Are you prioritizing the safety of your workers and the smooth operation of your lifting equipment? Look no further than DSM Hoist's team of knowledgeable hoist inspectors. With years of experience in the industry, our inspectors have the expertise and know-how to provide exceptional service that ensures maximum safety, reliability, and peace of mind for your manufacturing plant or Facility.

Why Choose DSM Hoist for Your Hoist Inspections?

1. Unparalleled Expertise

Our team of hoist inspectors consists of highly skilled and knowledgeable professionals who possess an in-depth understanding of hoists and their associated safety guidelines. With their comprehensive training and experience, they can effectively evaluate and identify potential issues, ensuring compliance with industry standards, government regulations, and best practices.

2. Thorough Inspections

At DSM Hoist, we leave no stone unturned when it comes to hoist inspections. Our knowledgeable inspectors conduct meticulous assessments of your hoisting equipment, examining every component and performing critical tests to detect even the smallest signs of wear, damage, or malfunction. By addressing potential issues proactively, we prevent costly breakdowns and downtime, avoiding unnecessary disruptions to your operations.

3. Customized Solutions

We understand that every business, plant & facility has unique requirements. That is why our inspectors tailor their approach to suit your specific needs. Whether you require a one-time inspection, regular maintenance inspections, or specialized evaluations, we provide customized solutions that align with your budget, timeframe, and operational constraints. Our goal is to help you maintain the efficiency and safety of your overhead cranes & hoists while minimizing risk and maximizing productivity.

4. Compliance and Risk Mitigation

By engaging our DSM team, you demonstrate a commitment to compliance and risk mitigation. Our inspectors stay up-to-date with the latest regulations and best practices, ensuring your equipment meets all necessary safety standards. We meticulously document our findings and provide detailed reports that contribute to your compliance records and risk management strategies. Rest assured, with our inspections, you'll be well-prepared for any external audits or inspections.

5. Efficiency and Cost Savings

Investing in our knowledgeable hoist inspectors can save you both time and money in the long run. By identifying potential issues early on, we help you avoid expensive repairs, replacements, and operation disruptions. Our proactive approach enhances the lifespan and performance of your lifting equipment, maximizing your return on investment. Plus, with optimized safety and reduced downtime, you can maintain a productive work environment and increase your bottom line.

Contact DSM Hoist Today and Elevate Your Safety Standards!

Why compromise on safety when you can collaborate with a team who prioritizes your well-being and operational success? Contact DSM Hoist today to schedule an inspection or learn more about our comprehensive range of services. Together, we can ensure safety, reliability, and peace of mind for your lifting operations.

des moines rigging training

Rigging is an intricate dance of balance and precision. And at the heart of this delicate operation lies one fundamental principle: centering the load.

When it comes to rigging, ensuring that the load is properly centered is paramount. This crucial step is often the difference between a smooth, hassle-free lift and a potential disaster.

By centering the load, we distribute its weight evenly, minimizing the risks of accidents, keeping product from damage, and protecting the lifting equipment from overly excessive strain. Proper weight distribution results in smoother movements and a rigging system that will be correctly & fully utilized without exceeding its safe operational limits.

If you are lifting an asymmetrical load, use Rigging equipment that is specially designed to handle your scenario. And ensure that there is mandatory proper training to use this special BTHLD. 1. it’ll keep operators safe 2. saves potential damage to the payload 3. saves costly accidents 4. avoids downtime 5. + you avoid delays in project completion.

MAKE THIS VITALLY IMPORTANT

We at DSM Hoist, have the experience, the knowledge and a passion for teaching.

Call us to visit about setting up a training program for your facility/s. We’d be honored.

DSM Hoist

Our focus is Overhead cranes & Hoists.

Look to us for all of your needs in the heavy lifting industry, here’s just a few…

ON site Safety Inspections.

Easily organized & applicable reports & documentations for your maintenance team and your OSHA compliance.

Hoist Operator & maintenance personnel training

Rigging & Rigging Hardware

Repair & Service

Load testing Service

New Hoist & Hoist parts

New Crane & overhead Lifting Equipment

OSHA Consultation

For answers to all of your questions, call us at

515-981-5600.

Iowa Hoist Repair

Do you have a hoist in need of repair? We have decades of experience & extensive knowledge in servicing all types of hoists.. Give us a call and lets get you back in the game.

Our number is 515-981-5600.

DSM Hoist Inspections and Training

Keeping your Hoist Operators safe with regular overhead crane & hoist inspections and supporting them with up-to-date Specialized Training makes the difference between a healthy happy facility and one that is quite frankly, a bit scary to work in.

When employees know that their superiors care about their safety, well being & success, the sense of appreciation is palpable and reciprocated & morale is noticeably higher. Employee turn over rates drop and production increases.

The time and investment to put these procedures into motion will pay off in remarkable ways.

DSM Hoist can assist you with the implementation process. Our staff of professional hoist inspectors and Operator Trainers can jump into action to help you in making this an easy & seamless transition.

Call us today to start the conversation. After our visit, we can present to you a competitive quote for our specialists to conduct your overhead crane & hoist inspections. While we’re visiting, please ask us about implementing our Hoist Operator Training into your facility as well. We’re here to help in any way we can.

1-515-981-5600

Below the Hook lifting devices

DSM Hoist specializes in the design, modification & fabrication of custom below the hook lifting devices (BTHLDs) for your application. Whatever your project requires, a lifting device can be designed to move your load safely, more easily & efficiently, saving you time and money.

We are a small business with decades of knowledge and experience to bring to your project.

Give us a call today and ask for Scott. Lets start a conversation to bring your vision to reality.

1-515-981-5600

DSM Hoist wishes you a...

weekend!

Des Moines Area Hoist Repair

Call DSM Hoist for all of your hoist needs. You have the option of dropping it off here at the shop or our team can come to you as well. When time is of the essence & you need to be up and running asap, we’ll be there for you.

Call us at 515-981-5600.

Hoist Operator training in Central Iowa

Training in hoist safety helps mitigate accidents.

Training in proper use of equipment helps prevent hoist breakdowns from misuse.

DSM Hoist wants to support you in being proactive with Operator training that will be an all around game changer for your facility.

Call us to visit about your training needs at 515-981-5600.

keeping everyone safe in central iowa

This must be number ONE on your list. Fortunately, we can assist you in this effort with timely overhead crane and hoist inspections, operator training courses, repairs as well as new installations. DSM Hoist is your “go to” in the heavy material lifting industry. Hey, while we’re thinking about it, Add Scott from DSM Hoist to your contacts right now. His phone number is 1-515-981-5600.

We look forward to visiting with you.

SUCCESSFUL MANUFACTURING STARTS WITH TRUSTWORTHY WORKSTATIONS from DSM HOIST

In the infancy stages, an up & coming manufacturing facility needs experience to pull from; ideally a consultant with the vested interest in guiding them to the best options available for their heavy lifting workstations.

With over 25 years experience, Scott, the owner of DSM Hoist knows the Overhead Crane and Hoist industry very well. With consideration to quality, reliability & cost effectiveness, Scott will listen and work with you to reach the greatest outcome and help set you on the course for a future of success.

Call us at 1-515-981-5600. We’re looking forward to visiting with you.

DSM Hoist Inspections

Seeking Hoist Wisdom...

is easy as dialing 1-515-981-5600.

DSM Hoist

At DSM Hoist, safety is at the forefront of our minds.

As professionals in the industry, we are all aware of the potential dangers associated with working beneath suspended loads. We know that even a slight mistake or equipment failure can lead to serious injuries or fatalities.

Here are 5 actions you should take to help ensure that operators stay vigilant while working in situations involving suspended loads:

1. Maintain a safe distance: Whenever heavy loads are being lifted or moved, it is essential to maintain an appropriate distance from the area directly beneath them. A minimum clearance zone should be established and communicated to all workers involved. Never be directly underneath a load. Even if you believe it is secure. It may shift unexpectedly or become unstable, endangering those beneath it.

3. Use proper barriers and signage: Employing appropriate barriers and signage around the work area is another critical safety measure. Clearly marking the no-entry zone beneath the suspended load will help prevent unauthorized personnel from entering the area. Barricades should be sturdy enough to prevent accidental entry and clearly visible to all workers.

4. Inspect equipment regularly: Regular equipment inspections are vital to identifying potential issues before they become safety hazards. Hoists, slings, shackles, and other lifting accessories should undergo robust inspection procedures to ensure their reliability and functionality. Any signs of wear, damage, or malfunctioning, they should be taken out of service & reported to maintenance staff immediately.

5. Provide comprehensive training: All personnel involved in tasks with suspended loads should receive comprehensive training on proper safety procedures. This training should encompass the use of lifting equipment, understanding load charts and recognizing potential hazards.

Happy Birthday, Olive!

If you’ve ever visited our shop, you already know little miss Olive. She greets everyone with a 21 bark salute…(because security is her top priority) and she resides over “her” staff with loyal & loving gestures… (because of course “HR” is her 2nd priority.)

Well, Today is Olive’s 6th birthday. She started her morning with a mountain of birthday presents, biscuits and treats to open. Some might say this 80lb. adorable creature is pampered, favored or dare I say, slightly spoiled, well, you’d be…. Wro….Right, you’d be right. lol.

Enjoy God’s gifts…every little one of them.

Olive asked me to end this post with a Big Loving Thank you & wet nosed smooch to her Mama & Aunty Joy who shower her with so much love, toys, treats and a special thank you to her Dad for blessing her with a fulfilling career in the hoist industry and a ride to work every day. thanks Dad!

Keeping the Crew SAFE

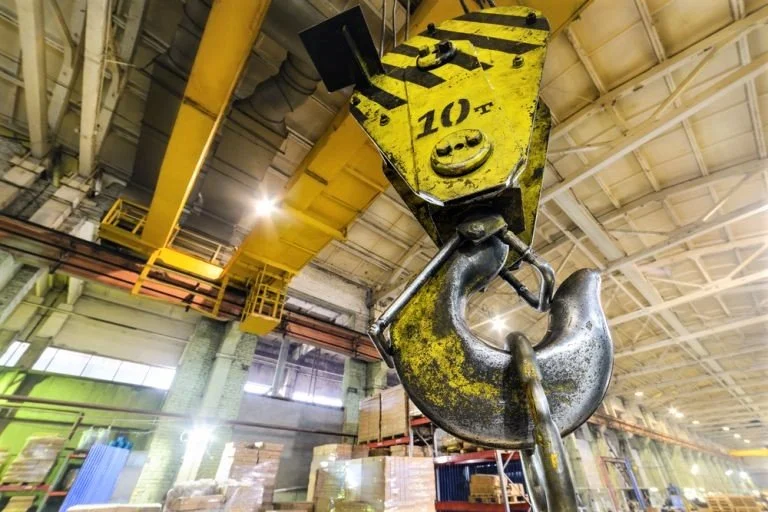

The Importance of Capacity Markings on Bridge Cranes

When it comes to the operation of bridge cranes, safety should always be the primary concern. These powerful machines are designed to lift and move heavy loads, and any miscalculation or oversight can result in disastrous consequences, such as structural failures or serious accidents.. Capacity markings on bridge cranes play a vital role in ensuring the safety of personnel and equipment.

With capacity markings, operators can easily identify the limits of the crane, ensuring that they operate within its safe working load. These markings eliminate any ambiguity and allow for responsible decision-making when it comes to selecting and moving loads.

Compliance with Regulations and Standards

Capacity markings are also a legal requirement. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, mandate that all lifting equipment must have clear and visible capacity markings. These markings must be easily readable from the ground level to ensure that operators, supervisors, and inspectors can access this critical information without difficulty.

During every overhead crane & hoist inspections that we perform, if any capacity marking raises concern, we are sure to note it in the detailed report that we provide to you.

Looking out for you Always,

Your friends from DSM Hoist

Bird's Eye View

This pic was taken in the early 1900s. The older I get the more fascinated I become with old photographs.. But when you come across a vision like this, my jaw literally drops. Will you look at that view? It’s amazing the determination, skills and bravery it took to do this job. Not to mention the trust that they had to have in their equipment. So this mammoth wire rope hoist made this skyscraper possible, but I’d place those brave men above the machine any day of the week. Much respect.

To view more historic photos like this one , I’ve added a link below.

Can you put this much trust in your fleet of hoists?

Here at DSM Hoist, our awesome specialists can raise your confidence to new heights by implementing Monthly & Annual inspections for your overhead cranes & hoists, perform routine maintenance, do repairs and even installations. Always remember, you’ve got a friend in the hoist industry & we are happy to serve you!

Overhead Crane and Hoist repair

Every intricate part of the manufacturing plant needs to work at it’s peak performance, right down to the heavy lifting work stations that you use. No one wants production down & every precaution to avoid it should be taken. I recommend outsourcing your monthly inspection task to specialists who focus solely on heavy lifting equipment. It’s the best way to stay on top of potential issues and avoid breakdowns.

But when a breakdown does occurs, you have an ally in DSM Hoist. Our experienced technicians are on call to assist you with 2 options to serve. We can repair your hoist/s here at our location or head right out to your facility to assist you with on-site repair.

Feel free to call us at anytime at our phone number 515-981-5600.

We want to be your “go to” in maintenance, repair and inspections of your overhead cranes & hoists.

Have an amazing week, friends

FREEDOM

Respect it, stand up for it, protect it & thank God for our freedom Every Day.

Have a beautiful weekend & Happy Independence Day.

From your friends at DSM Hoist