Be Aware of your surroundings & DO NOT stand near or in the path below a load being moved.

Add us to your Contacts

We're here for you!

That goes for every overhead crane and hoist owner/operator in the industry. If you are facing an issue with your heavy lifting equipment, your set up, the below-the-hook-lifting-devices you are using, you don’t have to navigate the problem alone. We got your back.. and we’ll do everything we can to get you the answers you need. Give us a call right here at DSM Hoist or submit a form and we’ll get in touch with you however you wish. talk to you soon!

Is It Time? Be sure to get your DSM Hoist inspections on the books

We are so honored to be helping the hoisting community.

If you aren’t a customer of ours yet, just want you to know that we look forward to helping you with all of your heavy lifting needs.

We’re just a phone call away

COMMUNICATE

In hoisting operations, miscommunication between the signaller and the operator can lead to injuries, fatalities, and property damage.

Only one person should signal the operator. But anyone can give the STOP signal and it must be obeyed immediately.

STUDY THE HOISTING SIGNALS AND KNOW THEM BETTER THAN THE BACK OF YOUR HAND.

No you didn't...

The Empire State Building was completed in 1931. This photo was taken sometime during the construction of that famous building.. I can barely even look at this..

If you're searching for Hoist inspections, you have come to the right place!

Rigging

WRONG WAY RIGHT WAY

Another prime cause of Hoist accidents is due to Poor Rigging.

DSM Hoist will train your operators on proper rigging techniques as well as pre shift inspections & hoist operation.

We provide Rigging Handbooks and pocket charts to aid operators in calculations on the go.

Inspect your equipment before every use.

Every manufacturing facility should provide the proper equipment and have it available for their operator’s use.

The efforts a facility puts into this along with proper education will ease the tension and raise the confidence of operators, greatly decreasing the risks of accidents and injury. Call 1-515-981-5600 and ask to talk with Scott.

Outsourcing for increased Safety

Know the capacity of your Crane and Hoist

A prime cause of accidents regarding overhead cranes and hoists is Overloading. Before any lift, always know the capacity of the overhead crane and hoist you are using. Also pay close attention to the lower lifting apparatuses (BTHLDs) for working load limit. And know the weight of the material you are lifting!

No you didn't...

Don’t even…..

Pictures (with motion) are worth 2 thousand words.

Here is what OSHA has to say on the subject of hoisting peeps.

Good morning, Hoist Community

Maintain the integrity of your equipment and stay OSHA compliant with Overhead crane & hoist Inspections from DSM Hoist.

Keeping everyone safe all begins with Knowledge. knowledge of your equipment, of rigging applications, procedure and daily inspection. Our training program is a classroom setting and hands on at your location, so that your operators are accustom to the equipment YOU use,

We’re excited to provide you with a program that will yield safety in your facility. Give us a call at 1-515-981-5600

Make it a great day!

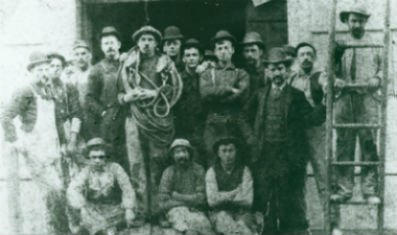

The older you get, the more fascinating history becomes...

Construction of the iconic Statue of Liberty began in 1875 by a team of skilled workers tasked with bringing this symbol of freedom to life. The workers, consisting of ironworkers, masons, and craftsmen, faced the challenging task of assembling the statue piece by piece.

The ironworkers meticulously connected the intricate framework, standing at over 150 feet tall, which would serve as the foundation for the statue's copper skin. The masons worked diligently to secure the copper pieces, carefully shaping and forming Lady Liberty's distinct features.

Despite facing harsh weather conditions and precarious working environments, the workers persisted with determination and expertise. Their craftsmanship and attention to detail ultimately led to the successful completion of this architectural marvel in 1886.

Through their dedication and skill, these construction workers played a significant role in not only erecting a statue but also in creating a timeless symbol that continues to inspire generations with its message of freedom and opportunity.

Putting a little blue sky in your day

When it comes to hoisting equipment near powerlines, make safety your #1 priority. By following regulations and guidelines, you will avoid injury, accidents or damage to equipment. Your work should be planned out with a qualified spotter to ensure safe distances are maintained. Review your plans, double check your plans. We want you safe out there.

Happy Easter

If you don’t know Him, you should.

…and realize the sacrifice He made was for you.

Rest, my friend

super heroes?

Safety in the factory and on the work site is by far the highest priority on your list of responsibilities each day. It’s frightening to consider all the scenarios that could happen, especially ones that training would have prevented. You want every employee equipped with knowledge!

If you have a solid training program in place, Hats off to you! That’s so great. If the current training program at your worksite has you feeling even a little bit anxious, hear me today. We can help you. ok, super heroes eradicating danger for all time is a blissful thought, but, can we make injury almost non existent? That IS & will Always be the goal. A majority of worksite accidents are avoidable, if you know

for instance, learning to use tag lines to guide and stabilize a load keeps you out of harms way. Learning how to calculate the “danger zone” in any given situation eliminates the chances of being injured by falling loads and/or flying debris if a BTHLD should fail.. Learning the proper way to PRE-INSPECT your machines & rigging equipment will significantly lower the chance of sling failure. This is just scratching the surface of the topics that we teach.

Please call us; lets talk about getting a training plan in place for your facility.

Here’s our number, 515-981-5600

BE SAFE

meet my new neighbor, maggie

Puppies make everything better, don’t they.

love, olive